Visual Inspection and Valve Service of Cylinders in Cyprus

Association of Scuba Service Engineers & Technicians: Visual Inspection and Valve Service of Cylinders in Cyprus

Introduction

Proper maintenance of scuba cylinders is crucial for diver safety and meeting international standards. Overlooking routine checks can lead to accidents or costly repairs. The Association of Scuba Service Engineers & Technicians (ASSET) in Cyprus plays a vital role in keeping standards high. They ensure technicians are skilled in visual inspections and valve servicing, extending cylinder life and preventing mishaps. These procedures aren’t just routine—they are life-saving practices that keep divers safe underwater.

The Role of the Association of Scuba Service Engineers & Technicians in Cyprus

Overview of the association

This professional body aims to promote safety and quality among cylinder service technicians in Cyprus. Its mission is to ensure all members follow strict procedures rooted in safety and technical competence. To join, technicians must meet specific training and experience criteria, adhering to high professional standards. The association also advocates for continuous professional development, keeping members updated with the latest safety practices and regulations.

Regulatory framework and compliance

- Cylinders in Cyprus are regulated under both local and EU standards. These include directives like EN10297:2024 and EU legislation governing gas cylinders. ISO 10297:2024 aims to ensure the safety, functionality, and compatibility of the valves themselves.

ASSET ensures its members comply with these codes of practice and guarantees safe and reliable cylinder servicing. Certification and training are mandatory; ASSET dive techs must undergo training to stay certified. Regular updates verify that asset service centres uphold safety and quality standards, protecting divers and consumers.

Visual Inspection of Scuba Cylinders in Cyprus

The purpose and importance of visual inspections

Visual inspections catch corrosion, dents, or cracks that could cause dangerous failures underwater. They are essential for safety by spotting issues before they become serious. Regulatory agencies and certain countries worldwide specify inspection timelines—usually every 2-5 years for the United Kingdom or every year, as we recommend for diving centres that depend on the usage of cylinders. Padi recommends having your tank visually inspected annually. This routine check is vital in preventing accidents caused by unnoticed damage or wear.

Step-by-step visual inspection procedures

- External check: Look for corrosion, cracks, gouges, or dents on the cylinder surface. Use a strong light to see hidden flaws and a pit gauge to measure and gouge.

- Valve area: Examine the valve threads for damage. Check the valve seat for corrosion or deformities that could cause leaks. A certified and calibrated Go No-Go tool must be used to test the tread on both valve and cylinder.

- Utilise tools: magnifying glasses, micrometres, go/no-go gauges and flashlights help inspectors spot tiny cracks or corrosion.

- Record findings: Take photos and log inspection results meticulously. Use checklists based on standards like EN10297 or US DOT to stay consistent.

Common issues identified during visual inspections

- Corrosion and pitting: Rust or surface corrosion weakens the metal. But it does not mean the cylinder fails.

- Cracks failures: Usually found in aluminium cylinders around the neck or valve area, potentially catastrophic. Eddy current testing (NDT) needs to be used.

- Damaged valve or neck: Worn threads or dents can cause leaks or damage during use. A certified and calibrated go/no-go plugs and rings must be used to check the pitch of the thread for accuracy.

Best practices and tips for inspectors

Maintain detailed records of every inspection; they must be kept for a minimum of 5 years. Photographs of any flaws for future reference. Use the ASSET standardised checklists aligned with safety standards and always wear protective gear while inspecting valves and cylinders. Consistent, thorough inspections can make the difference between a safe dive and an emergency.

Valve Service Procedures for Cylinders in Cyprus

Significance of valve maintenance

Valves are the control points for gas flow. If they leak or stick, it can be dangerous or disrupt a dive. Well-maintained valves last longer and keep cylinders safe and efficient. Regular servicing is key to preventing gas leaks and ensuring cylinders function correctly under pressure.

Disassembly and cleaning of valves

- Depressurise: Safely vent the cylinder before starting work. Make sure gas flow is completely empty from the cylinder.

- Separate parts: Carefully remove the valve from the cylinder. Use correct tools for removal of valves and torque spanner at the correct settings for replacement of the scuba valve.

- Clean: Use approved cleaners to remove dirt, debris, or corrosion. Check O-rings and seals, replacing worn ones. Do not use petroleum cleaning products.

- Inspect: Look for cracks, thread damage, or damage inside the valve body and components. Replace any faulty or defective parts.

Lubrication and reassembly

Choose lubricants suitable for high-pressure gas systems. Christolube is recommended, and apply sparingly to O-rings and moving parts. Reassemble the valve carefully, aligning all threads and fittings correctly. Conduct a leak test after reassembly to confirm a perfect seal.

Troubleshooting common valve issues

- Sticking valves: Usually caused by dirt or corrosion. Service valve cleaning often solves the problem.

- Leaks: Typically, due to old O-rings, damaged seals or improper reassembly. Replace seals and check installation.

- Cross-threading: Can occur when reattaching the valve. Always ensure threads are aligned before tightening. Check and double-check you have the correct valve for the correct cylinder thread M25x2, G3/4 or NPSM.

Best practices and safety precautions

Always wear gloves and eye protection. Use manufacturer-approved tools for disassembly and reassembly. Dispose of damaged seals and parts responsibly, preventing environmental hazards. Follow safety guidelines strictly to avoid accidents during service.

ASSET Industry Standards, Certification, and Training in Cyprus

Relevant standards and certification bodies

Cyprus follows global and European standards like EN10297, DOT, and CE marking for cylinders and valves. Local authorities also require certified technicians to perform inspections and repairs. Certification ensures technicians have the right skills, knowledge and experience to carry out safe servicing of scuba valves and cylinders.

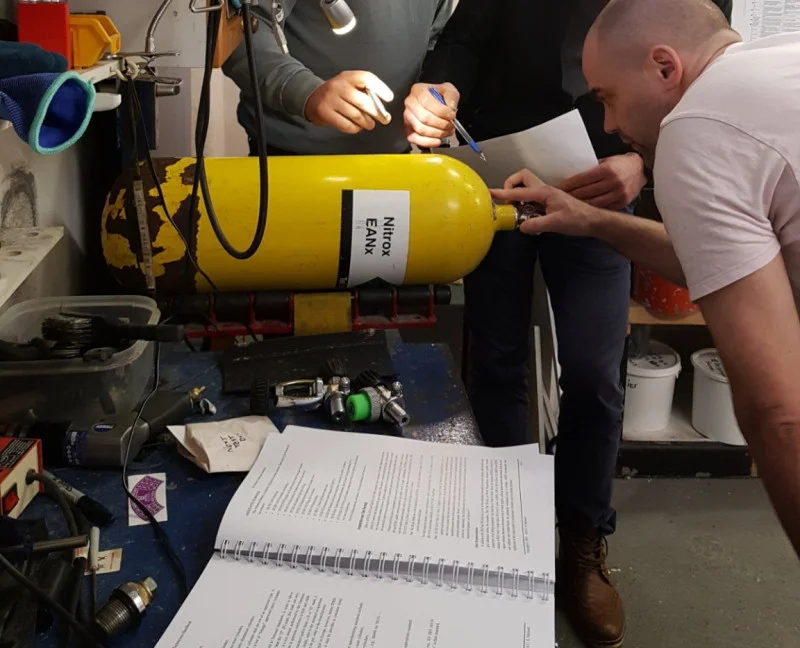

Training programmes and workshops

The Association of Scuba Service Engineers & Technicians (ASSET) provides comprehensive training courses on visual inspection and cylinder valve servicing in Cyprus. These ASSET workshops aim to enhance skills and update technicians on the latest safety practices. Continuous education reduces errors and improves service quality.

Ensuring quality and safety through accreditation

ASSET Service centres in Cyprus can achieve accreditation by meeting strict criteria and passing quality audits. Certification guarantees customers that the work is reliable and standards are met. Regular audits and internal controls help maintain high quality levels.

Conclusion

Choosing to properly inspect and service scuba cylinders isn’t just about compliance—it’s about saving lives. A well-trained, certified technician plays an important key role in keeping dive equipment safe beneath the water’s surface. You must adhere to international standards, and by making thorough scuba cylinder visual inspections and scuba valve maintenance, we can prevent accidents and extend the lifespan of cylinders. Staying updated with ASSET and industry practices, continuing education, and strict quality control will ensure Cyprus remains a safe place for every diver. Dive safe and always trust the professionals who follow best practices.

Should you wish to get traing and become a Asset Dive Technician please contact us.