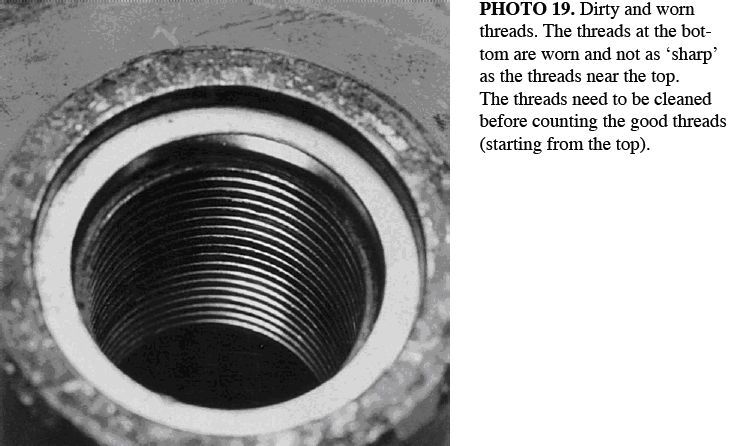

Unusual DOT3 AL 3000psi Scuba Cylinder Threads ‘Condemn’

Unusual DOT 3AL 3000 Threads ‘Condemn’ Thread corrosion that has propagated along the grain boundary

- INSPECTORS NOTE – The problem above (left hand photo) is absolutely not visible from the small thumbnail above in any way Click on the image to download a high resolution 400Kb Photo to view the problem running along every thread. The right hand photo is presented from the manufacturers inspection guide. This is a really difficult inspection call and often requires a manufacturers decision.

- Manufacturers Comments The (high resolution left hand photo) appears to me to be corrosion that has propagated along the grain boundary. I have seen many times in scuba where corrosion will begin between the 8th and 12th thread of the cylinder, at the exact location where the valve ends in the cylinder. This is most likely due to the moisture that sits at the junction between two dissimilar metals. The corrosion is greatest in the grain boundary, inter-granular corrosion, and propagate along the grain. The grains predominately run perpendicular to the axis of the threads and when attacked by corrosion can appear as linear indications similar to folds or cracks – but are not. It appears in the second picture that some metal is missing in the 11th thread – a condition typically associated with corrosion, never a crack. In checking a cylinder with an eddy current device usually a 2 thread indication is reason for reject. This cylinder may be rejected for a linear condition, corrosion, that extends more than 2 threads but it is not rejected for a manufacturing defect.

Manufacturer Decision:- In a case like this we would offer our replacement program to the owner of this cylinder.