3/4″ NPSM Cylinder Neck Thread Inspection and Testing European

3/4″ NPSM Cylinder Neck Thread Inspection and Testing

Aligned with EN ISO 18119 Test-House Practice

The 3/4″–14 NPSM (National Pipe Straight Mechanical) thread is a parallel thread commonly found on aluminium scuba cylinders manufactured for international markets. Under EN ISO 18119, inspection of the cylinder neck threads forms a mandatory part of periodic inspection and testing, with the objective of ensuring mechanical integrity, correct thread form, and safe valve compatibility.

Role of Neck Thread Inspection under EN ISO 18119

EN ISO 18119 requires that, during periodic inspection, the cylinder valve shall be removed and the internal neck area, including threads and sealing surfaces, shall be inspected for defects that could compromise safety. For 3/4″ NPSM threads, this inspection focuses on:

- Mechanical damage to the thread form

- Evidence of incorrect valve installation or thread mismatch

- Surface defects, cracking, corrosion, or distortion

- Condition of the O-ring sealing land

Identification of 3/4″ NPSM Threads

Correct identification of the neck thread standard is critical. A 3/4″ NPSM thread is a parallel thread with an elastomeric O-ring seal, and it must not be confused with metric threads such as M25 × 2, which differ in pitch and sealing geometry. Incorrect valve fitment is a recognised cause of thread damage and may necessitate enhanced inspection.

Inspection Methods

Inspection is conducted using a combination of visual examination, dimensional gauging, and non-destructive testing where required:

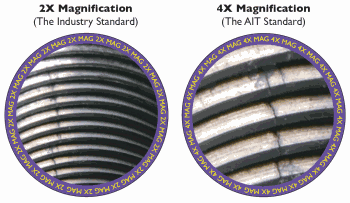

- Visual inspection is performed using adequate illumination and magnification to examine the full thread length and sealing surface.

- Thread gauging may be carried out using full-form plug gauges to verify thread profile and engagement.

- Eddy-current testing may be applied where required by cylinder manufacturer guidance, test-house procedures, or where damage is suspected, particularly in aluminium alloys known to be susceptible to neck cracking.

Acceptance Criteria

A cylinder neck with a 3/4″ NPSM thread is acceptable for continued service only when:

- Threads are free from cracks, deformation, galling, or excessive wear

- The sealing surface is intact and undamaged

- No evidence exists of forced or mismatched valve installation

- Any applied non-destructive testing indicates no rejectable defects

Documentation

All findings must be recorded in the cylinder inspection record in accordance with EN ISO 18119, including thread condition, inspection methods used, and any non-destructive testing applied.